Robotics in Engineering & Construction

Robotics is rapidly reshaping the engineering and construction industries by automating labor intensive tasks, improving precision, and enhancing worker safety. As projects grow in complexity and timelines shrink, robotics provides the technological edge needed to build faster, safer, and more sustainably.

At Emmaty, we focus our efforts on finding state of the art machinery that allows us to provide a better service, taking advantage of these new technologies in robotics, as shown below.

What Is Construction Robotics?

Construction robotics refers to the use of automated machines and intelligent systems to perform tasks on engineering and building projects. These robots can operate autonomously or semi autonomously and are often supported by AI, sensors, computer vision, and advanced control systems.

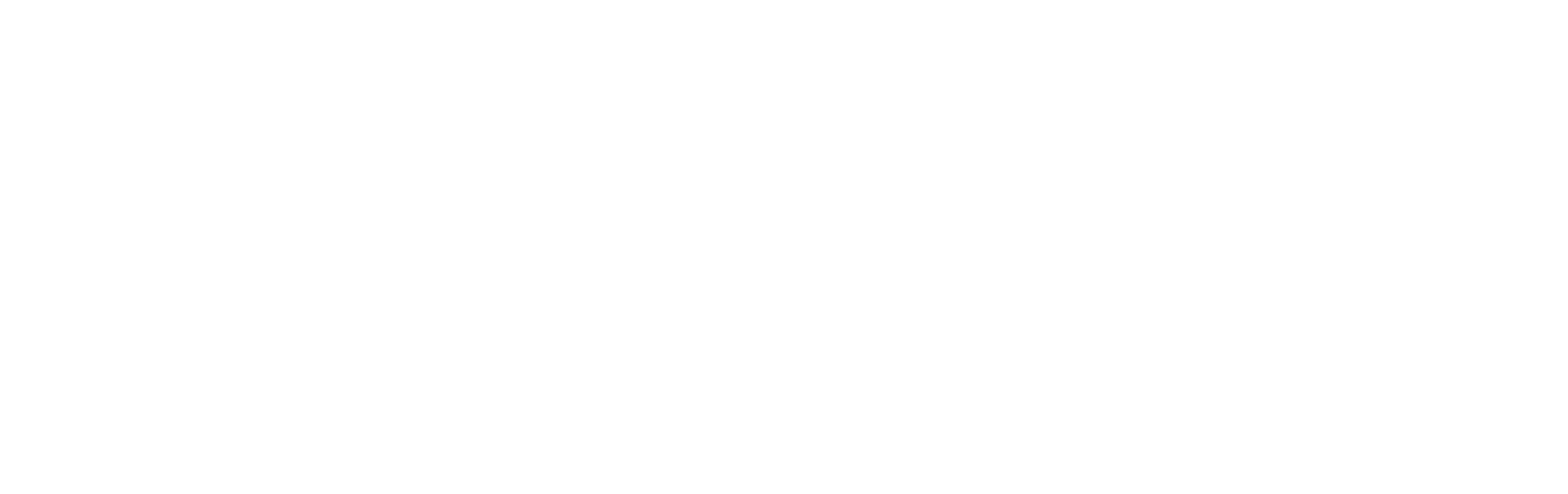

Common forms include:

Robotic arms for welding, drilling, and 3D printing.

Autonomous vehicles (bulldozers, excavators, haul trucks).

Drones for surveying, inspection, and monitoring.

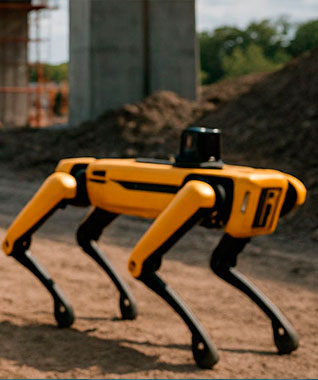

Humanoid or mobile robots for inspections and repetitive tasks.

Exoskeletons to enhance human strength and reduce fatigue.

Autonomous Heavy Machinery

Self driving excavators and bulldozers.

Automated grading and earthmoving.

Precision digging using GPS and LiDAR.

Minimizes human error and speeds up large scale projects.

Key Areas Where Robotics Is Used

Automated Site Inspection and Monitoring

Robotic platforms and autonomous devices capture real time jobsite data, helping teams track progress, identify risks, and ensure compliance with design specifications.

3D Scanning and Reality Capture

Robotic laser scanners collect high accuracy site measurements, enabling faster verification, reduced rework, and seamless alignment between design and field conditions.

Material Handling and Logistics Support

Robotic solutions assist with moving and organizing materials, reducing manual strain, improving workflow efficiency, and minimizing downtime on active sites.

Precision Construction and Installation

Robotics supports tasks requiring high accuracy, such as alignment, positioning, and assembly. This improves build quality and ensures consistent results across projects.

Printing & Robotic Fabrication

Large-scale robotic 3D printers construct walls, houses, and building components

Reduces material waste and speeds up construction cycles

Enables complex geometries and innovative architectural designs

What’s trending in Robotics for engineering and construction